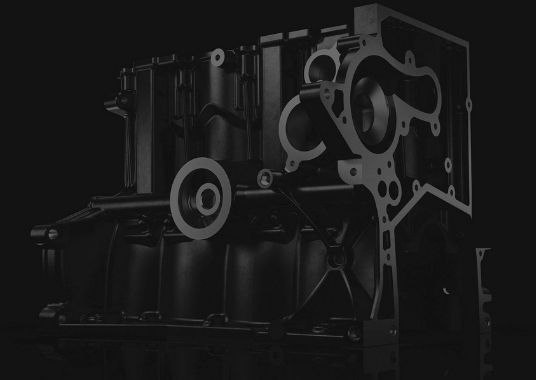

ecoCasting – the sustainable casting process

The new casting process from Fritz Winter

Savings in raw materials, emissions, energy, product weight and costs, and at the same time high-quality lightweight products - with the innovative ecoCasting casting process we have revolutionized the iron foundry. The process does not require molding sand. Instead, we cast the iron directly into core packages, thus saving a variety of resources. In line with the objective of our eco solutions, ecoCasting brings economy and ecology into harmony. As a development partner for international customers in the automotive, commercial vehicle and hydraulics industries, we will be pleased to support you in your challenge from the idea to the finished product with this sustainable process.

Sustainable eco solutions from Fritz Winter

ecoCasting for CAR

Because lightweight construction concepts are our passion, we have completely reinvented the foundry in iron casting with the ecoCasting process.

ecoCasting for CV

With our ecoCoating process, we produce drastically emission-reduced and EURO-Norm-7-compliant brake discs.

ecoCasting for E-Motor

Under ecoMelting, we summarise all measures that are intended to lead to a CO2-neutral foundry that is independent of fossil fuels.

Sie haben Fragen zu unserem Fertigungsverfahren ecoCasting? Gerne stehen wir Ihnen bei Ihrem Anliegen zur Verfügung.